- E-mail: admin@yaweitransformer.cn

- Tel: +86-18862719076

Oil-immersed transformer is an indispensable key testing equipment in the power industry, and it is the basic testing equipment used by power stations, power supply bureaux and other units to do AC voltage withstand test. It is mainly used for testing various electrical products, electrical components, insulating materials and other insulation strength experiments under the required voltage, evaluating the insulation level of products, detecting the insulation shortcomings of the tested products, and considering the ability of overvoltage.

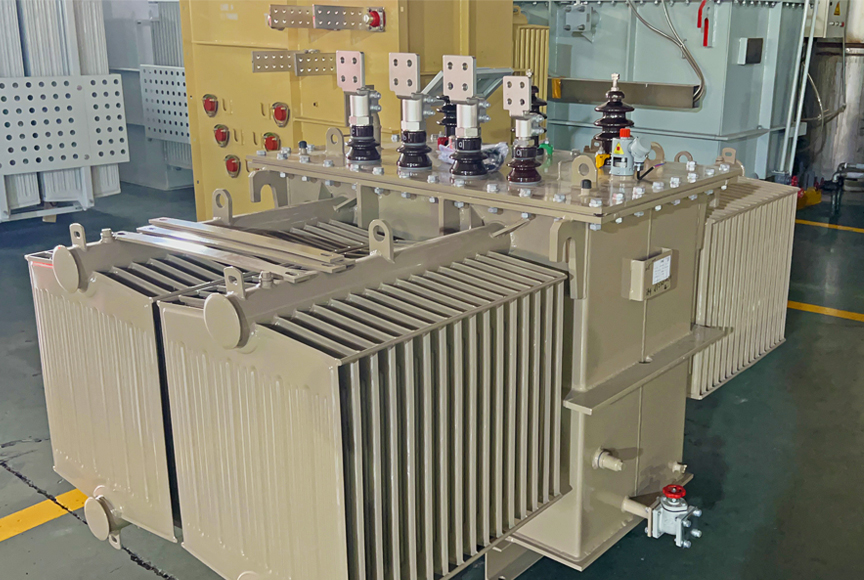

According to different types, oil-immersed transformers can also be divided into oil-immersed transformers, dry test oil-immersed transformers, inflatable oil-immersed transformers and so on. Among them, oil-immersed transformer is a common one, and the following is to understand the composition and advantages of oil-immersed transformer in detail.

Oil-immersed transformer, also known as oil-immersed transformer. 1000kVA or above oil-immersed transformer, outdoor signal thermometer must be installed, and can be connected to distant signals. 800kVA or above oil-immersed transformer should be equipped with gas relay and pressure protection equipment, 800kVA following oil-immersed transformer according to the use of demand, negotiate with the manufacturer, can also be installed gas relay.

The oil-immersed transformer is mainly composed of iron core, winding, oil tank, oil pillow, insulated pipe, tap changer and gas relay.

1. Iron core

The core is the magnetic part of the transformer. Hysteresis loss and eddy current loss should be generated during operation and hot. In order to reduce the burning consumption and reduce the volume and weight, the core is composed of cold-tied grain-oriented silicon steel sheet with a strong permeability index lower than 0.35mm. According to the layout method of winding in the iron heart, there are iron core type and iron shell type.

In large capacity transformers, in order to make the loss of heat from the core can be adequately carried by the insulating oil during circulation to achieve a better cooling effect, the core is often equipped with cooling oil channels.

2. Winding

The winding and the core are the key components of the transformer. Because the winding itself has a resistance or a loop resistance at the interface, the I2Rt knows to generate heat. Therefore, the winding cannot be based on the current stronger than the rated voltage for a long time. In addition, depending on the short circuit capacity, a large magnetic field force will be generated on the winding and damage the transformer. The basic winding has two kinds: the same boat type and the overlapping type.

The key fault of oil-immersed transformer winding is the short circuit between turns and the short circuit of the opposite case. Interturn short circuit is mainly caused by insulation aging, or mechanical damage caused by the over-load of the transformer and its crossing short circuit. When the oil level in the transformer is reduced, resulting in the exposed oil level of the winding, it can also cause inter-turn short circuit; In addition, when crossing short circuit, because of the effect of overcurrent, the winding deformation, so that the insulation suffered mechanical damage, will also bring inter-turn short circuit. In the case of interturn short circuit, the current in the short circuit winding may exceed the rated value, but the entire winding current may not exceed the rated value. In this case, the gas protection action, the situation is serious, the differential protection equipment will also act. The cause of short circuit to the housing is also due to insulation aging or oil return, oil level reduction, or caused by lightning and operating overvoltage. In addition, when crossing short circuit occurs, the winding deformation due to overcurrent will also bring short circuit to the housing. When the case is short-circuited, it is generally gas protection equipment action and grounding protection action.

Step 3: Fuel tank

The body (winding and core) of the oil-immersed transformer is packed into a tank filled with transformer oil, and the tank is welded with steel plates. The tank of the medium and small transformer is composed of the shell and the cover. The body of the transformer is placed in the shell, and the cover can be opened to lift out the body for maintenance.