- E-mail: admin@yaweitransformer.cn

- Tel: +86-18862719076

First of all, the manufacture of ultra-high voltage transformers requires rigorous design and planning. Engineers will make detailed design drawings according to customer requirements and specifications. These design drawings include the structure, material, size and other parameters of the transformer to ensure that the transformer produced meets the standards.

Then, distribution transformer manufacturers will purchase high-quality raw materials. The manufacture of ultra-high voltage transformers requires the use of high-strength steel, insulation materials, copper wire, etc., to ensure the stable and reliable performance of the transformer. Only by selecting the right raw materials, can the ultra-high voltage transformer meet the requirements.

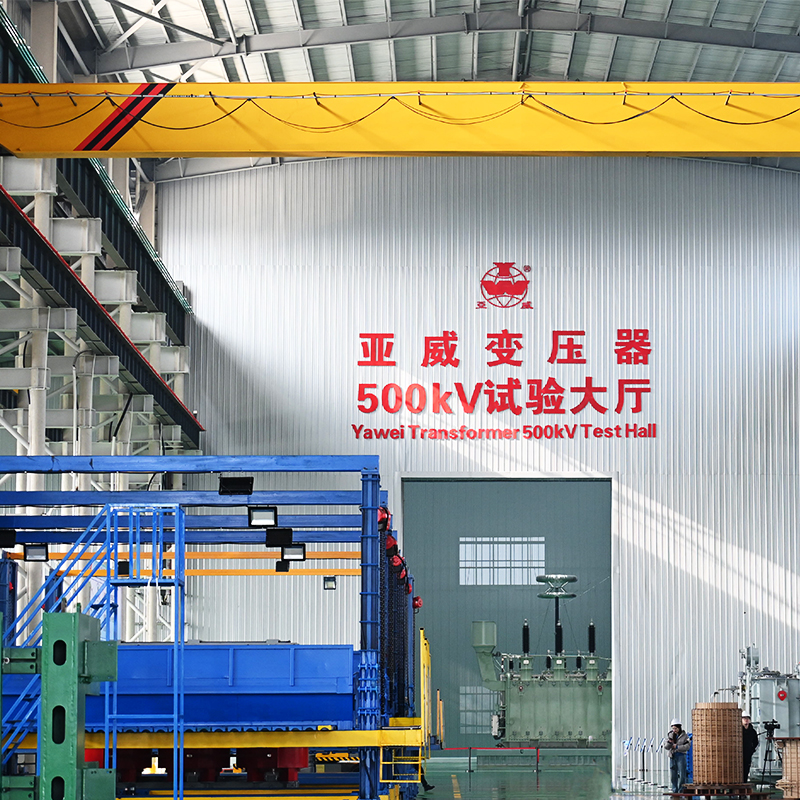

During the manufacturing process, workers assemble and weld according to the design drawings. This process requires a high degree of skill and experience, ensuring that the individual components are securely connected without leakage or other safety hazards. At the same time, workers also need to carry out strict tests and inspections to ensure that the performance of the transformer meets the standard requirements.

Finally, the UHV transformer will be insulated and decorated. Insulation treatment can effectively prevent leakage or short circuit in the working process of the transformer, and improve the safety and stability of the transformer. The appearance decoration is to beautify the appearance of the transformer and improve its overall quality.

Through the above process, distribution transformer manufacturers can produce high-quality ultra-high voltage transformers to provide customers with reliable power equipment support. Only by continuously improving the technical level and constantly improving the manufacturing process can we produce better transformer products to meet the market demand.