- E-mail: admin@yaweitransformer.cn

- Tel: +86-18862719076

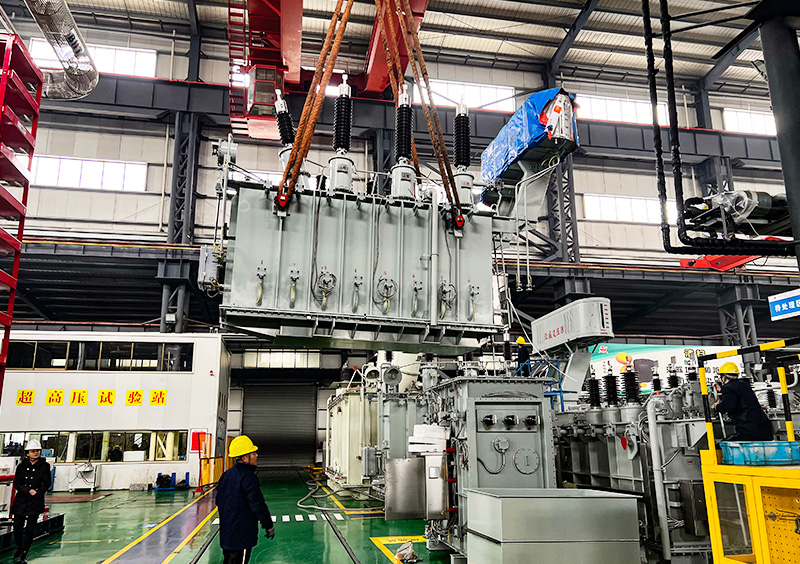

Oil-immersed transformer is an important equipment in power system, its running state directly affects the stability and security of power system. In order to ensure the normal operation of the transformer, timely fault diagnosis and elimination is particularly critical. The following is an introduction to the fault diagnosis and removal methods of oil-immersed power transformers.

First of all, the fault diagnosis of oil-immersed power transformers generally includes the following steps: First, preliminary inspection, including appearance inspection and basic functional testing. By observing whether there is oil leakage, deformation and other phenomena on the outside of the transformer, its operating state can be preliminarily judged. The second is to use instruments and equipment for detailed testing, such as the use of insulation resistance tester, winding DC resistance tester, etc., to detect the insulation performance of the transformer and whether the winding resistance is normal. The third is to analyze the operation data of the transformer, such as oil temperature, load current, insulation resistance, etc., by comparing the normal value with the actual value, to determine whether there is an abnormal situation.

In terms of troubleshooting, you first need to develop a repair plan based on the diagnosis. If the transformer is found to have insulation aging problems, replace the insulation oil or repair the insulation materials in time. If the transformer overheats, it may be that the load is too large or the cooling system is faulty, and it is necessary to check the operation of the cooling system, and adjust the load or repair the cooling system. For internal faults, such as winding short circuit or poor contact, it is usually necessary to disassemble the transformer for inspection and, if necessary, to replace or repair the winding.

In addition, regular maintenance and maintenance is an important measure to prevent transformer failure. Regular transformer inspection, testing, timely detection of potential problems, can effectively avoid failure. Maintenance work includes checking oil levels and oil quality, cleaning radiators and cooling systems, and checking electrical connections and grounding devices.

In short, the fault diagnosis and elimination of oil-immersed power transformers need to combine a variety of methods, comprehensively detect the indicators of the transformer, and take corresponding repair measures according to the actual situation. At the same time, regular maintenance and maintenance can effectively prevent the occurrence of failures to ensure the stable operation of the transformer.